Concrete Panels: The Ultimate Guide to Sustainable Building Materials

- Jeevan Kasturi

- Sep 1, 2025

- 7 min read

In an era where environmental consciousness meets architectural innovation, concrete panels have emerged as one of the most promising sustainable building materials for modern construction. These versatile, durable, and eco-friendly components are revolutionizing how we think about green building practices while delivering exceptional performance and aesthetic appeal.

What Are Concrete Panels?

Concrete panels, particularly precast concrete panels, are prefabricated building components manufactured in controlled factory environments before being transported to construction sites. These panels can serve various functions including structural walls, facades, flooring systems, and architectural features. Unlike traditional cast-in-place concrete, these panels offer superior quality control, reduced waste, and enhanced sustainability benefits.

Types of Concrete Panels

Precast Concrete Panels: Manufactured off-site in controlled conditions, ensuring consistent

quality and reduced environmental impact.

Architectural Concrete Panels: Designed with aesthetic considerations, featuring various textures, colors, and finishes for building facades.

Structural Concrete Panels: Engineered to bear loads and provide structural integrity while maintaining energy efficiency.

Insulated Concrete Panels: Incorporate insulation layers for enhanced thermal performance and energy savings.

The Sustainability Advantage: Why Concrete Panels

Are the Future

Reduced Carbon Footprint

The sustainability credentials of concrete panels are impressive and constantly improving. Recent innovations in 2025 have introduced carbon-negative materials that can significantly enhance concrete's environmental profile. Scientists have developed new carbon-negative building materials using seawater, electricity and carbon dioxide (CO2), with the material holding over half their weight in CO2 to become a carbon sink.

Traditional concrete production accounts for approximately 8% of global CO2 emissions, but precast concrete panels offer several advantages that reduce this impact:

Factory Production Efficiency: Manufacturers produce precast concrete in a controlled environment, with the process being more efficient and using less energy than onsite pouring, while offering significant environmental benefits including reduced CO2 emissions

Minimized On-site Operations: Traditional construction methods often involve extensive on-site operations, leading to higher energy consumption and increased greenhouse gas emissions, which precast panels help avoid

Energy Efficiency and Thermal Performance

One of the most compelling sustainability features of concrete panels is their exceptional thermal performance. The thermal mass properties of concrete provide natural energy efficiency that translates to significant long-term savings:

25% Energy Savings: Thermal mass provides flatter temperature swings and energy savings

of up to 25%, with precast concrete reducing heating and cooling costs by 25%

Long-term Operating Efficiency: Precast concrete's thermal mass absorbs and releases heat slowly, equating to long-term energy savings through years of cooling and heating the building, especially when combined with insulation

Enhanced Comfort: When properly insulated, precast panels can significantly reduce energy costs by minimising heat transfer, creating a more comfortable indoor environment while lowering utility bills

Material Efficiency and Waste Reduction

Precast concrete panels demonstrate superior material efficiency compared to traditional construction methods:

Reduced Material Usage: Precast uses less steel, concrete, and water compared to cast-in-situ

Precision Manufacturing: Factory production ensures optimal material usage with minimal waste

Quality Control: Controlled environments result in fewer defects and material rejections

Recyclability and Circular Economy

The circular economy benefits of concrete panels are substantial:

End-of-Life Recycling: Precast concrete is friendly to downcycling, breaking apart with minimum energy and retaining original qualities, with old panels becoming concrete aggregate in new mixes for future buildings

Industry Leadership in Recycling: The construction industry recycles over 30 million tons of materials annually, making it one of the world's largest recyclers

Recyclable Components: Precast concrete is recyclable, contributing to sustainable construction practices

Exceptional Durability and Longevity

Concrete is without doubt the most durable material, with examples like the Pantheon in Rome or the Colosseum demonstrating its solidity. This exceptional durability translates to:

Extended Building Lifespan: Precast structures are designed to last for decades, remaining resilient against environmental factors and reducing replacement needs

Lower Life-cycle Costs: Concrete provides energy efficiency, long life cycle, and lower life-cycle costs

Reduced Maintenance Requirements: Durable concrete panels require minimal maintenance over their lifespan

Environmental Benefits in Detail

Carbon Sequestration Potential

The latest developments in concrete technology are pushing the boundaries of sustainability. New carbon-negative building materials can lock away CO2 permanently and turn it into valuable materials for manufacturing concrete, cement, plaster and paint, transforming CO2 into valuable building materials using seawater and electricity.

Natural Resource Conservation

Precast concrete is made from natural ingredients like sand, gravel, and cement which are abundantly available in nature, minimizing environmental impacts related to transportation over long distances or industrial extraction processes.

Transportation Efficiency

Transporting precast concrete elements to construction sites is more efficient than delivering raw materials and mixing concrete on-site, reducing the carbon footprint

associated with construction logistics.

Design Versatility and Aesthetic Appeal

Modern concrete panels offer architects and designers unprecedented creative freedom:

Architectural Flexibility: Panels can be molded into various shapes, textures, and patterns to achieve unique aesthetic goals.

Color and Finish Options: Advanced manufacturing techniques allow for a wide range of colors, textures, and surface treatments.

Integration with Other Materials: Concrete panels can be seamlessly integrated with glass, steel, and other building materials for hybrid designs.

Modular Design Benefits: Standardized panel systems enable faster construction and easier future modifications or expansions.

Applications Across Building Types

Residential Construction

Multi-story apartment buildings

Single-family homes

Townhouse developments

Affordable housing projects

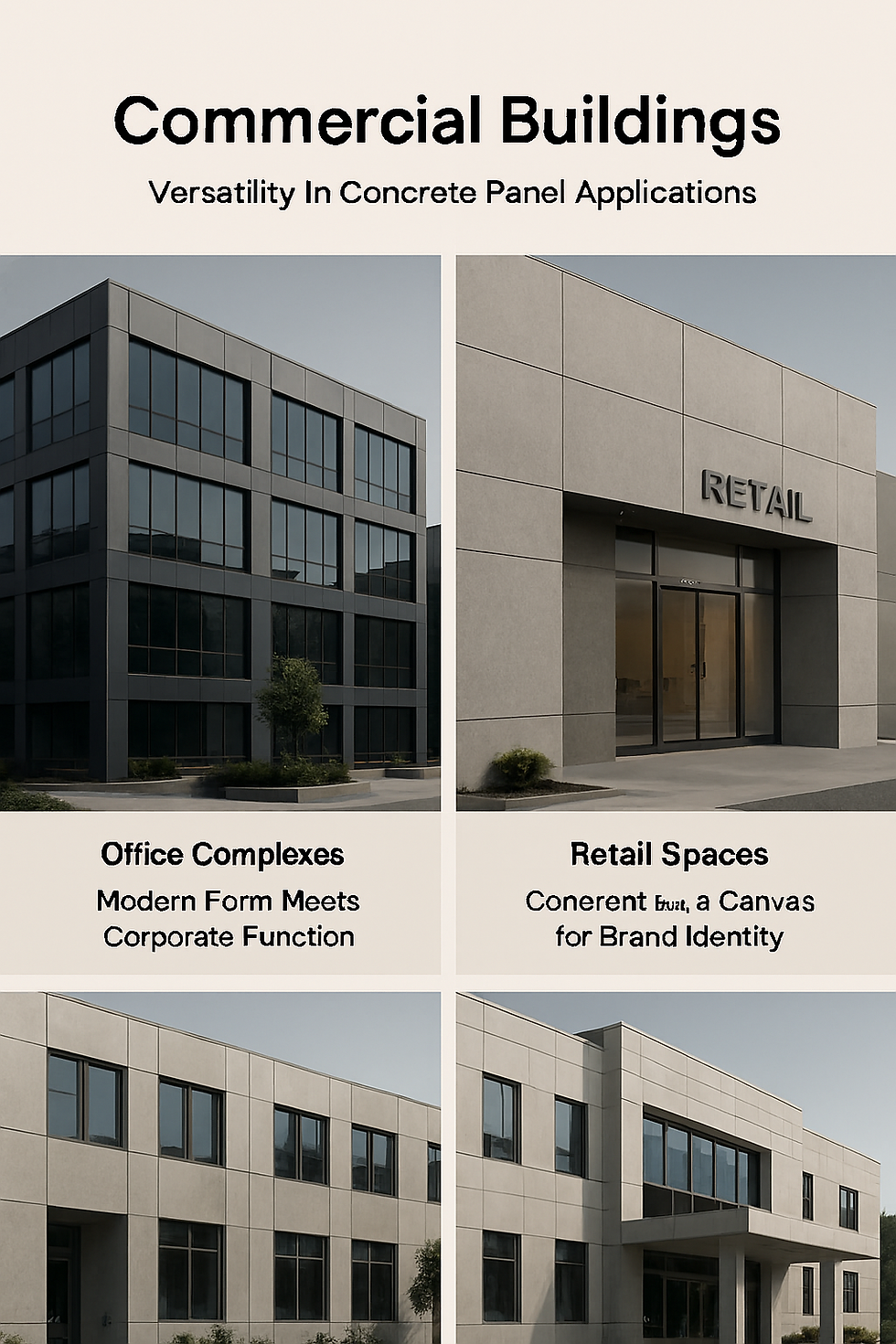

Commercial Buildings

Office complexes

Retail spaces

Educational facilities

Healthcare buildings

Industrial Applications

Warehouses and distribution centers

Manufacturing facilities

Data centers

Agricultural buildings

Infrastructure Projects

Bridge components

Retaining walls

Sound barriers

Water treatment facilities

Installation and Construction Benefits

Speed of Construction

Precast concrete panels significantly reduce construction timelines through:

Concurrent manufacturing and site preparation

Weather-independent factory production

Faster on-site assembly processes

Reduced curing time requirements

Quality Assurance

Factory production provides:

Consistent quality control standards

Predictable material properties

Reduced construction defects

Enhanced structural performance

Safety Improvements

Reduced on-site construction activities

Controlled manufacturing environment

Minimized worker exposure to harsh weather

Standardized installation procedures

Economic Advantages

Cost Efficiency

While initial costs may be comparable to traditional methods, concrete panels offer significant long-term economic benefits:

Reduced Labor Costs: Faster installation reduces labor requirements and associated costs.

Energy Savings: Thermal mass properties provide ongoing energy cost reductions throughout the building's life.

Lower Maintenance: Durable concrete requires less frequent repairs and maintenance interventions.

Extended Lifespan: Longer building life reduces replacement costs and provides better return on investment.

Value Engineering

Concrete panels enable value engineering through:

Optimized structural design

Integrated architectural and structural functions

Reduced material redundancy

Streamlined construction processes

Innovative Technologies and Future Trends

Smart Concrete Systems

Emerging technologies are integrating sensors and smart materials into concrete panels for:

Structural health monitoring

Energy optimization

Building automation integration

Predictive maintenance capabilities

Advanced Manufacturing Techniques

3D printing of concrete components

Robotic panel production

AI-optimized mix designs

Automated quality control systems

Enhanced Insulation Integration

Modern panels incorporate:

High-performance insulation materials

Thermal bridge elimination

Vapor barrier integration

Continuous insulation systems

Environmental Certifications and Standards

Green Building Certifications

Concrete panels contribute to various green building certification programs:

LEED (Leadership in Energy and Environmental Design): Points for energy efficiency, material selection, and construction waste reduction.

BREEAM: Credits for material lifecycle assessment and energy performance.

Living Building Challenge: Support for material transparency and carbon reduction goals.

Industry Standards

The Concrete Sustainability Council (CSC) promotes and demonstrates concrete as a sustainable building material through certification systems for responsibly sourced concrete, covering the complete concrete supply chain.

Best Practices for Sustainable Implementation

Design Optimization

Right-sizing: Avoiding over-specification (generally the stronger the concrete, the more cement is required) can make the construction process more efficient.

Efficient Design Methods: Using more efficient design and delivery methods, modularization and digital rehearsals to avoid design clashes can cut emissions.

Lifecycle Thinking: Consider the entire building lifecycle from production to end-of-life recycling.

Material Selection

Choose locally sourced materials when possible

Specify recycled content requirements

Consider carbon-negative concrete options

Evaluate supplementary cementitious materials

Installation Considerations

Plan for efficient transportation and logistics

Optimize panel sizing for reduced joints

Consider future disassembly and recycling

Implement proper sealing and weatherization

Maintenance and Lifecycle Management

Preventive Maintenance

Regular visual inspections

Joint sealant maintenance

Surface cleaning protocols

Early repair of minor damages

Performance Monitoring

Energy consumption tracking

Thermal performance assessment

Structural integrity evaluation

Environmental impact monitoring

Challenges and Solutions

Common Concerns

Initial Cost: While upfront costs may be higher, lifecycle cost analysis typically favors concrete panels due to durability and energy savings.

Transportation Weight: Modern logistics and planning can effectively manage the transportation of heavy panels.

Design Limitations: Advanced manufacturing techniques are expanding design possibilities continuously.

Innovative Solutions

Lightweight concrete formulations

Hybrid panel designs combining multiple materials

Modular systems for easier handling

Advanced connection systems for improved performance

Future Outlook and Innovations

The concrete panel industry continues to evolve with exciting developments on the horizon:

Carbon-Negative Concrete

Recent breakthroughs in carbon-negative concrete technology promise to transform the industry's environmental impact, potentially making buildings carbon sinks rather than carbon sources.

Recycled Content Integration

The world's first fully recycled concrete building demonstrates the potential for circular economy principles in construction, pointing toward a future where all concrete panels incorporate significant recycled content.

Digital Manufacturing

Advanced manufacturing technologies including AI optimization, robotic production, and digital twin modeling are improving efficiency and reducing waste in panel production.

Conclusion

Concrete panels represent a mature yet rapidly evolving sustainable building solution that addresses multiple environmental, economic, and performance challenges in modern construction. Their combination of durability, energy efficiency, recyclability, and design versatility makes them an excellent choice for projects seeking to minimize environmental impact while maximizing long-term value.

As the construction industry continues to prioritize sustainability, concrete panels offer a proven pathway toward carbon-neutral and eventually carbon-negative building practices. The industry is working to make concrete even better through initiatives like the ACA Roadmap to Carbon Neutrality, ensuring that concrete panels will remain at the forefront of sustainable construction for decades to come.

The integration of innovative technologies, improved manufacturing processes, and circular economy principles positions concrete panels as a cornerstone of sustainable building practices. For architects, developers, and builders committed to environmental responsibility without compromising on performance or aesthetics, concrete panels provide an ideal solution that meets the demands of both present needs and future sustainability goals.

To know more , reach us on hr@smartplot.in or https://www.surfaceelements.in/. Smart Plot Surface has best solution in designs and for External construction materials. https://maps.app.goo.gl/fn77MDRqp3GTAQy88

Comments