A Complete Guide of Earthy Clay Pavers

- Jeevan Kasturi

- Jun 23, 2025

- 7 min read

What Are Clay Pavers

Clay pavers are solid, brick-like units made from natural clay that has been formed, dried, and fired at high temperatures. Unlike concrete pavers, which are manufactured from cement, sand, and aggregate, clay pavers are created from earth itself, making each one subtly unique in color, texture, and character.

These pavers typically come in rectangular shapes but can be found in various dimensions, with the most common being

Standard: 4" × 8" (10cm × 20cm)

Modular: 3.75" × 7.5" (9.5cm × 19cm)

Roman: 4" × 12" (10cm × 30cm)

The thickness typically ranges from 1.25" to 2.75" (3cm to 7cm), depending on the intended application.

The Rich History of Clay Pavers

Clay paving has an illustrious history dating back thousands of years. Ancient civilizations in Mesopotamia used fired clay bricks for roads and public spaces as early as 4000 BCE. In medieval Europe, clay pavers created the characteristic streets of towns and cities many of which still exist today, testament to their incredible durability.

The industrial revolution brought mechanized production methods, but the essential process remained unchanged: clay extracted from the earth, shaped, and fired to create a material of exceptional strength and beauty.

Today's clay pavers honor this heritage while incorporating modern manufacturing precision and enhanced performance characteristics.

The Manufacturing Process From Earth to Art

The journey from raw clay to finished paver involves several crucial steps:

Extraction: Clay is mined from quarries where high-quality deposits exist.

Preparation: The raw clay is crushed, ground, and mixed with water to create a workable consistency. Sometimes, additives are included to enhance color or performance.

Forming: The clay mixture is extruded through dies to create long columns in the desired shape, which are then cut to length.

Drying: The formed pavers are dried slowly and carefully to remove moisture without cracking.

Firing: The dried pavers are fired in kilns at temperatures between 1,900°F and 2,100°F (1,040°C and 1,150°C). This transforms the clay through vitrification, creating the final hardened product.

Cooling and Sorting: After firing, the pavers cool gradually and are sorted for quality, color consistency, and dimensional accuracy.

What makes this process so remarkable is how it transforms soft earth into a product that can withstand centuries of foot traffic, vehicle weight, and environmental exposure.

Natural Properties That Set Clay Pavers Apart

Clay pavers offer numerous performance advantages that explain their enduring popularity

Exceptional Durability

Properly installed clay pavers can last for centuries with minimal maintenance. The firing

process creates a material that

Resists compression forces

Withstands freeze-thaw cycles

Maintains structural integrity under heavy loads

Endures constant foot traffic

Color Permanence

Unlike concrete pavers that can fade over time, clay pavers maintain their rich color indefinitely. The color is not a surface treatment but runs throughout the material, created by the mineral content of the clay and the firing process.

Slip Resistance

The natural texture of clay provides excellent slip resistance, making these pavers ideal for pool surrounds, patios, and other areas where water may be present.

Thermal Mass

Clay pavers absorb heat during the day and release it slowly at night, helping to moderate temperature in outdoor spaces and potentially reducing energy costs when used indoors.

Fire Resistance

Having already been through the firing process, clay pavers are naturally fire-resistant, offering an additional safety feature for outdoor living areas.

Design Versatility: Colors, Textures, and Patterns

Clay pavers offer remarkable design flexibility through their varied colors, textures, and laying patterns.

Color Palette

The natural color range of clay pavers spans from soft buffs and sandy tones through warm terracottas to deep burgundies and chocolates. These colors emerge from the mineral

content of the clay and the firing conditions

Iron produces reds and browns

Calcium creates buff and cream tones

Manganese contributes purples and dark browns

Many manufacturers offer blended colors that incorporate multiple hues for a more dynamic appearance.

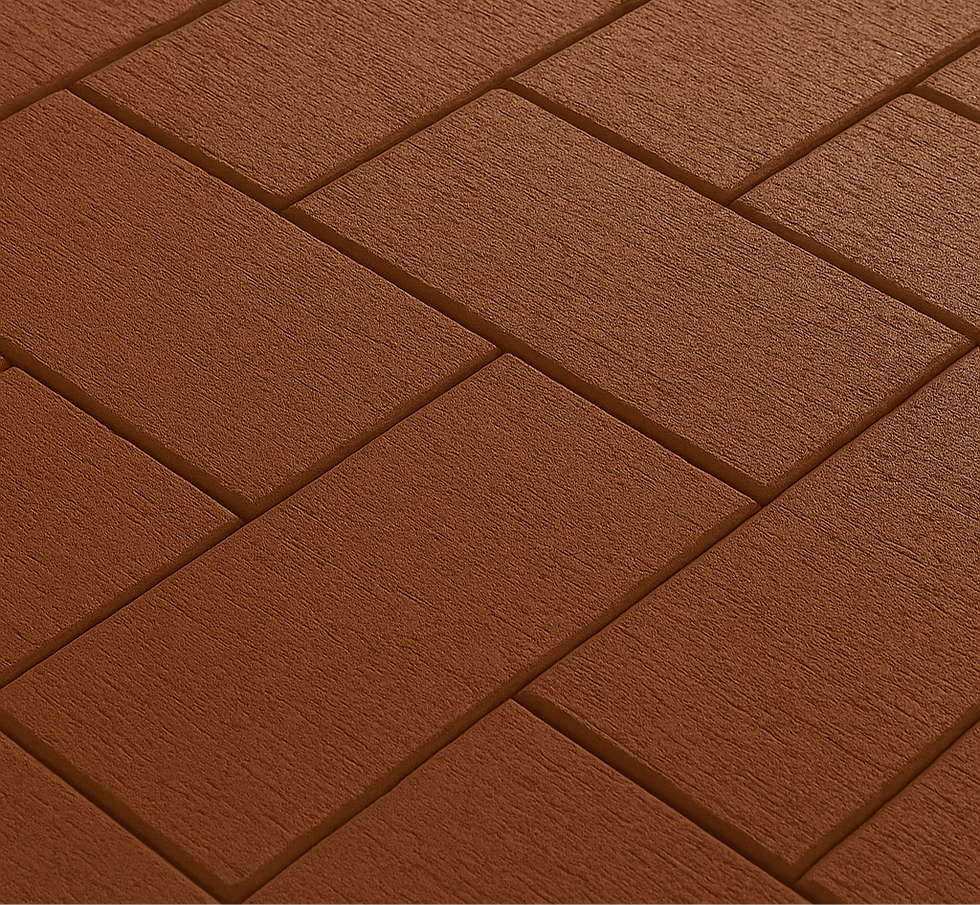

Surface Textures

Clay pavers come in several texture options

Smooth: With subtle variations that catch the light

Wirecut: With a slightly rough, handcrafted appearance

Tumbled: With softened edges that create an aged, antique look

Embossed: With patterns pressed into the surface

Laying Patterns

The arrangement of pavers dramatically affects the final aesthetic. Popular patterns include:

Running Bond: A simple offset pattern resembling a traditional brick wall

Herringbone: A dynamic zig-zag pattern that distributes weight effectively

Basketweave: An interwoven appearance with pavers laid perpendicular to each other

Stack Bond: A grid pattern with joints aligned

Circular: Radial patterns that create focal points

Random: Mixed sizes creating an organic, less formal appearance

Applications: From Driveways to Indoor Floors

Clay pavers excel in numerous applications, both outdoors and indoors

Outdoor Applications

Patios and Terraces: Creating inviting outdoor living spaces with natural warmth

Walkways and Garden Paths: Offering durable, attractive connections between landscape features

Driveways: Providing long-lasting access with distinctive character

Pool Surrounds: Delivering slip-resistant surfaces that stay cooler underfoot than many alternatives

Retaining Walls: When specialized wall pavers are used

Public Spaces: Creating plazas and streetscapes with historical resonance

Indoor Applications

Kitchen Floors: Offering warmth and easy maintenance

Entryways and Mudrooms: Providing durable flooring that welcomes and withstands traffic

Sunrooms: Creating a seamless indoor-outdoor transition

Accent Walls: Adding texture and warmth to interior spaces

Environmental Benefits: A Sustainable Choice

Clay pavers stand out as an environmentally responsible choice for several reasons

Natural Materials

Made primarily from abundant clay, these pavers require minimal processing compared to manufactured alternatives.

Longevity

With lifespans measured in centuries rather than decades, clay pavers reduce the resource consumption associated with replacement cycles.

Energy Efficiency

While the firing process does require energy, the extreme durability means this energy investment is amortized over a much longer useful life than most alternatives.

End-of-Life Recyclability

Clay pavers can be crushed and repurposed at the end of their (very long) life, often finding new use as landscape fill or aggregate.

Reduced Heat Island Effect

Lighter-colored clay pavers reflect more sunlight than asphalt or concrete, helping to moderate ambient temperatures in urban environments.

Permeability Options

Permeable clay paver systems allow rainwater to infiltrate into the ground, reducing runoff and supporting groundwater recharge.

Installation Fundamentals

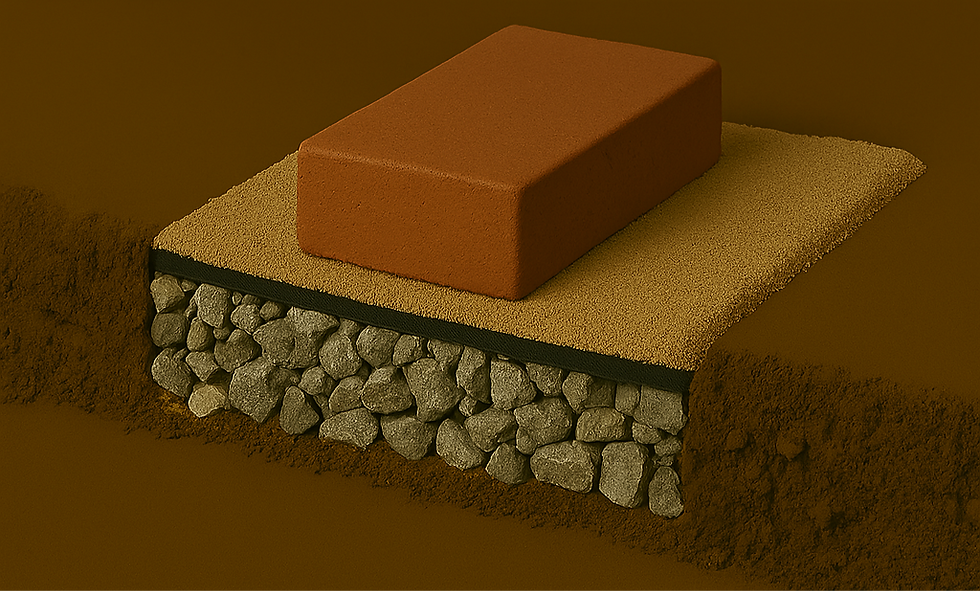

Proper installation ensures the performance and longevity of clay paver surfaces

Base Preparation

The foundation of any successful paver installation is proper base preparation

Excavate to the required depth (typically 6-12 inches)

Install geotextile fabric to prevent weed growth and separate soil from base materials

Add and compact a base layer of crushed stone or gravel

Apply a leveling layer of coarse sand

Edge Restraints

Edge restraints prevent lateral movement and maintain the integrity of the paver surface.

Options include

Concrete curbs

Metal edging

Plastic edging systems

Existing structures (walls, buildings)

Sand Joints

After laying the pavers, fine sand is swept into the joints to:

Lock pavers in place

Prevent weed growth

Allow minimal movement without cracking

Sealing Considerations

Unlike concrete pavers, clay pavers generally don't require sealing. However, optional sealers can

Enhance colors

Provide stain resistance

Stabilize joint sand

Reduce efflorescence

Maintenance: Minimal Effort for Maximum Longevity

One of the most appealing aspects of clay pavers is their minimal maintenance requirements

Routine Care

Sweeping: Regular sweeping removes debris and prevents organic material from

accumulating.

Rinsing: Occasional rinsing with a garden hose maintains the pavers' appearance.

Spot Cleaning: For stains, mild soap and water is usually sufficient.

Periodic Maintenance

Joint Sand Replenishment: Over time, some joint sand may be lost and need replacement.

Weed Management: While proper installation minimizes weed growth, occasional removal may be necessary.

Efflorescence Management: If white deposits appear (rare with quality clay pavers), they can be removed with specialized cleaners.

Cost Considerations: Investment Value

Clay pavers typically represent a higher initial investment than concrete alternatives, with prices ranging from $2 to $4 per square foot for materials. Installation costs vary by region and complexity but typically add $6 to $12 per square foot

However, this premium is offset by

Exceptional longevity

Minimal maintenance costs

Enhanced property value

Superior aesthetic appeal

When considered over their lifetime, clay pavers often prove more economical than alternatives requiring replacement or refinishing

Regional Variations and Design Influences

Clay paver traditions vary worldwide, reflecting local materials, climate considerations, and cultural preferences

Mediterranean Styles

Characterized by warm terracotta tones and organic layouts that create casual, inviting spaces suited to outdoor living.

Northern European Approaches

Featuring more structured patterns and deeper red tones, often incorporating decorative elements and precise geometric designs.

American Colonial Influences

Drawing on early American traditions with red and brown tones in formal patterns that complement traditional architecture.

Contemporary Interpretations

Modern designs often combine clay pavers with contrasting materials like steel, glass, or concrete for striking juxtapositions of texture and color.

Case Studies: Clay Pavers in Action

Historic Downtown Revitalization: Charleston, SC

When Charleston revitalized its historic market district, clay pavers were the natural choice for pedestrian areas. The result honors the city's heritage while providing durable surfaces that have withstood hurricanes, tourist traffic, and the coastal climate for decades.

Sustainable Campus Design: University of California

UC Davis incorporated permeable clay pavers in its award-winning sustainable campus redesign, reducing stormwater runoff while creating aesthetically pleasing gathering spaces that reference the region's agricultural heritage.

Residential Transformation: Modern Farmhouse

A residential project in Vermont used clay pavers throughout the landscape, creating pathways, patios, and a driveway that perfectly complement the modern farmhouse architecture while providing all-season functionality in a harsh climate.

Expert Insights: Designer Perspectives

"What draws me to clay pavers again and again is their authenticity," says landscape architect Maria Rodriguez. "Each project takes on its own character because the material itself has character—subtle variations in color and texture that you simply can't replicate with manufactured products."

Interior designer James Chen adds, "For transitional spaces between indoors and outdoors, clay pavers create continuity. They bring warmth inside while extending living space outward, all with a material that improves with age."

Conclusion: Timeless Appeal for Contemporary Spaces

Clay pavers represent that rare combination of historical authenticity and contemporary relevance. They connect us to building traditions thousands of years old while meeting modern needs for sustainability, durability, and aesthetic sophistication.

Whether you're creating a garden path, renovating a historic property, or designing a contemporary outdoor living space, clay pavers offer a material connection to the earth that enriches our built environment and stands the test of time.

To know more , reach us on hr@smartplot.in or https://www.surfaceelements.in/. Smart Plot Surface has best solution in designs and for External construction materials. https://maps.app.goo.gl/fn77MDRqp3GTAQy88

Comments